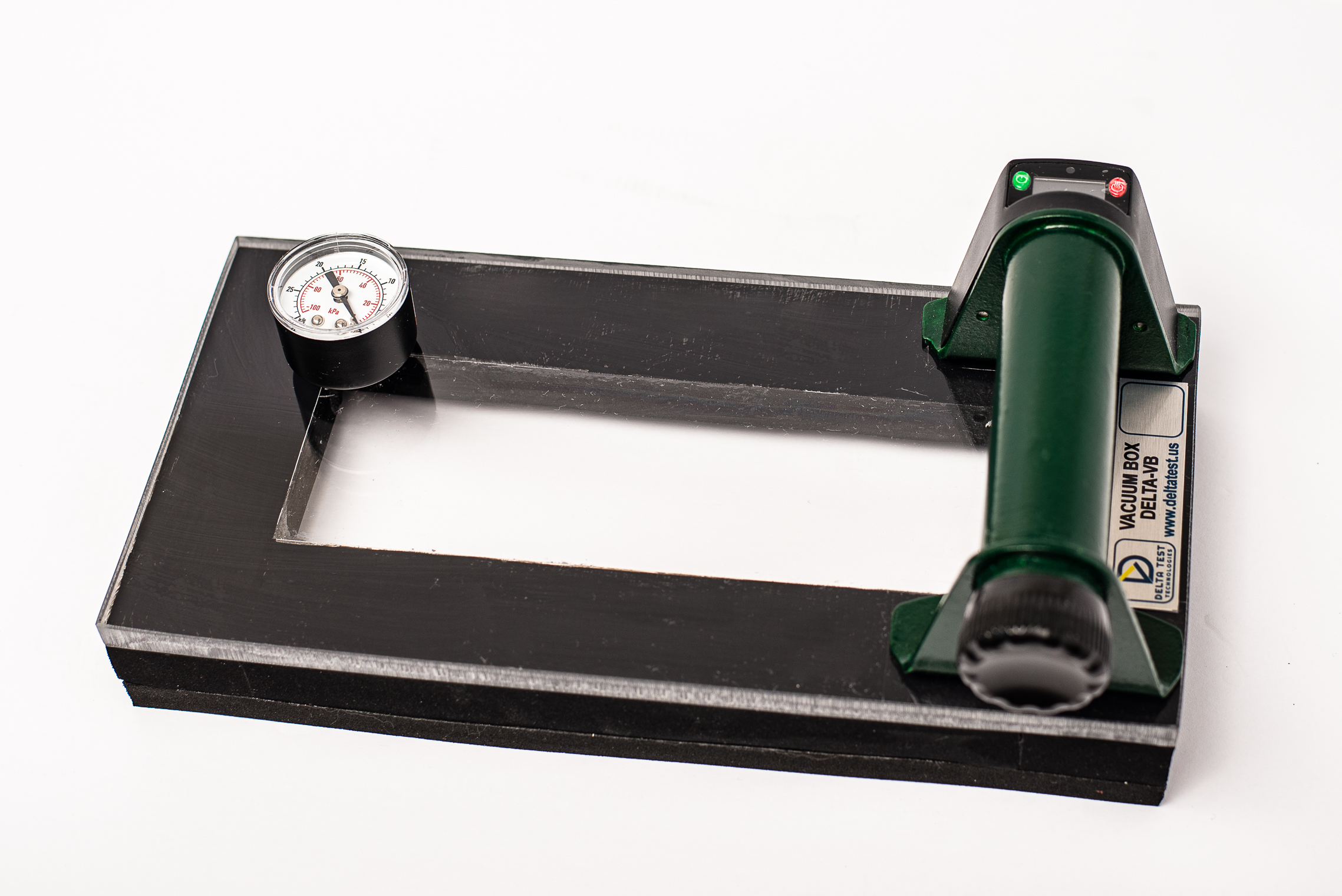

Vacuum Box DELTA VB300-A – Portable Autonomous NDT Leak Detection Tool

Vacuum Box DELTA VB300-A – Portable Autonomous NDT Leak Detection Tool

The DELTA VB300-A Vacuum Box is a compact, lightweight, and fully autonomous tool designed for non-destructive testing (NDT) of welded joints in sheet metal structures. Ideal for tank bottoms, protective shells, vessel elements, pipelines, and other products with one-sided seam access, it ensures precise leak detection in both field inspections and maintenance operations.

Using the bubble emission method, the DELTA VB-300-A detects through-thickness defects by creating a controlled vacuum in the attached chamber. Any leaks are visualized as gas bubbles in a foaming indicator solution applied to the welded seam, allowing accurate defect identification. This method complies with international standards, including ASTM E515-11 and DIN EN 1593, making it a reliable choice for professional NDT applications.

Key Features & Advantages:

-

Autonomous and portable – no external vacuum pumps, hoses, filters, or AC power required.

-

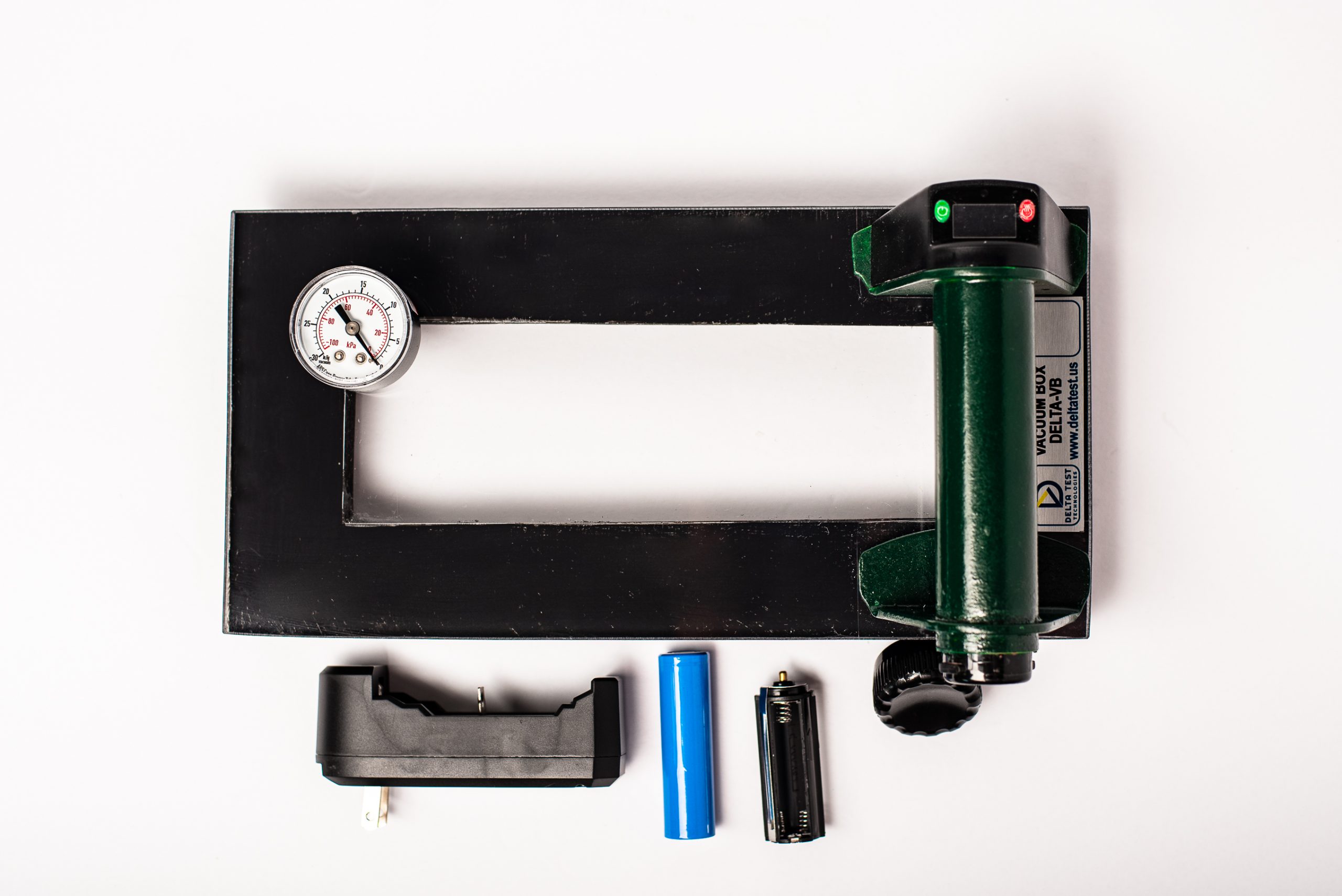

Battery-powered – operates on a 3.7V, 2200 mAh rechargeable battery, providing up to 4 hours of continuous operation.

-

Lightweight & compact – vacuum box weighs just 1.3 kg; full kit weighs only 2.5 kg, easy to transport in the included case.

-

Fast and efficient – completes vacuum cycles in seconds (30 s to reach -0.6 atm for a 0.013 mm² leak), up to 130 cycles per battery charge.

-

Safe low-voltage operation – 3.7V power supply ensures maximum field safety.

-

Complete kit included – vacuum box, spare battery, charger, transport case, and product passport.

Technical Specifications:

-

Dimensions (L×W×H): 300 × 150 × 100 mm

-

Window size: ≥ 220 × 70 mm

-

Battery type: 18650 Li-ion, 3.7V, 2200 mAh

-

Charging time: ≤ 6 hours

-

Maximum vacuum cycles per charge: 130

Why Choose the DELTA VB300-A:

This innovative vacuum box concept eliminates the need for external pumps, hoses, and electrical connections, offering unmatched mobility, safety, and ease of use. Its compact and lightweight design enables inspections in confined or remote locations, while the integrated battery-powered pump ensures fast, precise, and repeatable leak detection.

The DELTA VB300-A sets a new standard in portable NDT equipment, combining efficiency, safety, and compliance with international standards for reliable, high-precision inspection of welded joints and sheet metal structures.

Order the DELTA-VB300-A Today

Streamline your non-destructive testing (NDT) processes with the DELTA-VB300 Vacuum Box.

Contact us now for more details or to request a quote!

We also offer a variety of technical diagnostic and non-destructive testing equipment to meet your needs.