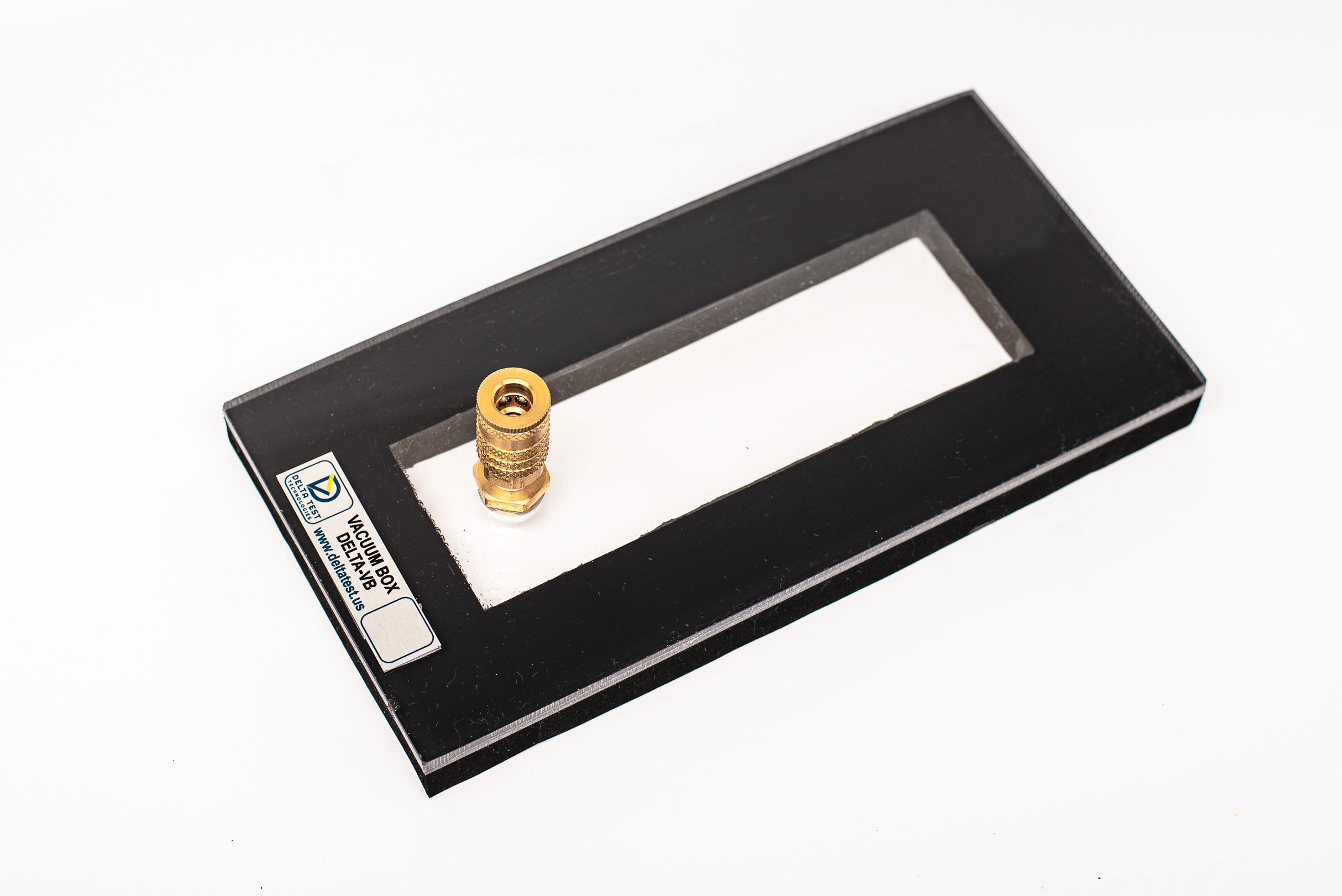

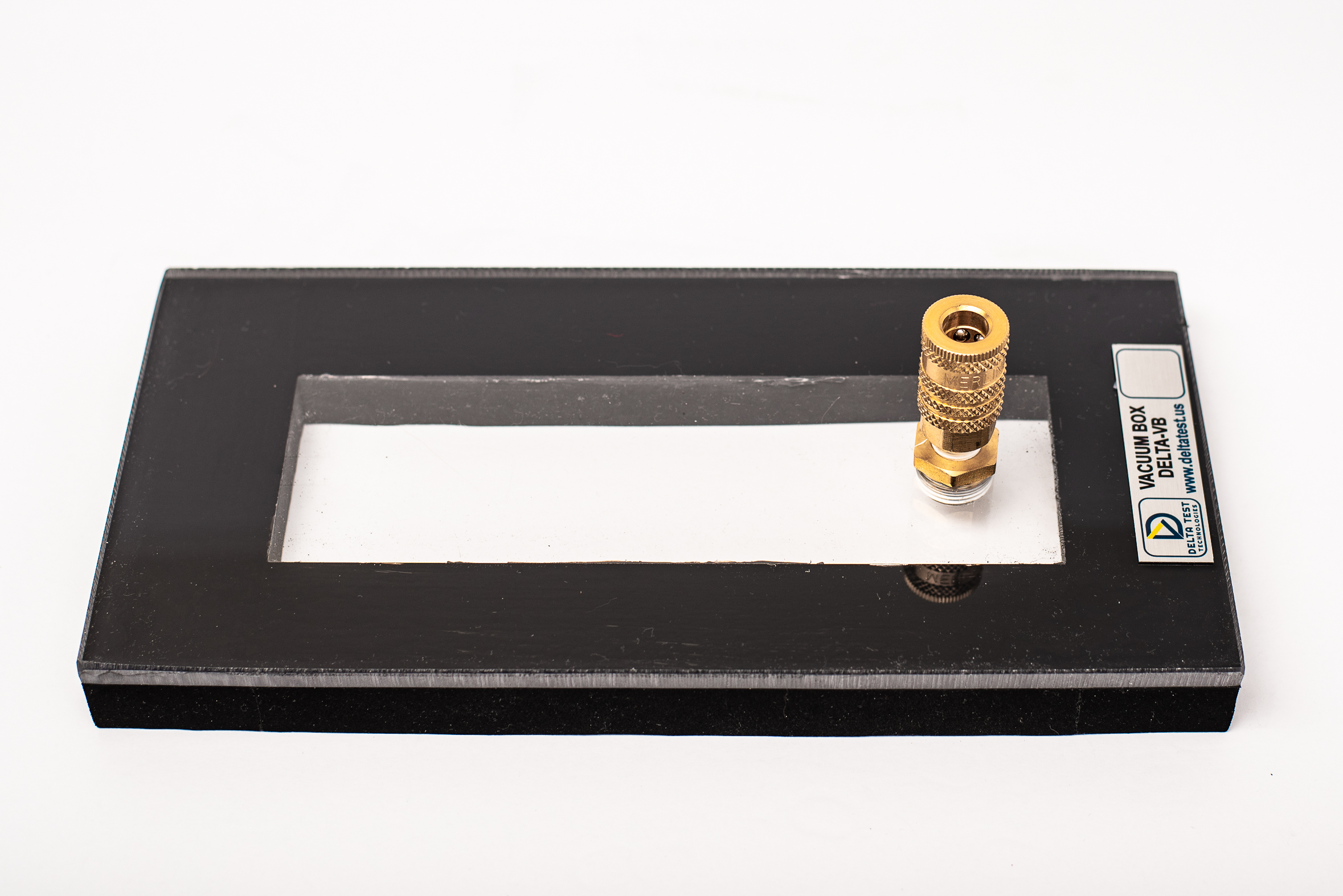

Vacuum box DELTA-VB300

Vacuum Box DELTA-VB300 for Leak Detection in Welded Joints

The Vacuum Box DELTA-VB300 is a compact and efficient tool designed for leak detection in welded joints of sheet metal structures. It is ideal for inspecting tank bottoms, protective shells, vessel elements, pipelines, and other products with one-sided seam access. Using the bubble emission method, the DELTA-VB300 ensures compliance with international standards, including ASTM E515-11 and DIN EN 1593, making it a reliable choice for non-destructive testing (NDT).

This vacuum box is designed for use with an external vacuum pump. The vacuum pump is not included in the standard scope of delivery and can be ordered additionally.

Key Features

- High-Precision Leak Detection: Accurately identifies through-hole defects using vacuum-based pressure drop methods.

- Compact and Portable: Designed for ease of use in field and workshop settings.

- Standards Compliance: Meets industry benchmarks such as ASTM E515-11, DIN EN 1593, GOST 3242-79, and DSTU EN1593-2015.

- Efficient Monitoring: Capable of inspecting large areas quickly and effectively.

Principle of Operation

The Vacuum Box DELTA-VB300 detects leaks using a simple and effective bubble emission method:

- A foaming indicator solution is applied to the welded joint.

- The vacuum box creates an air pressure drop in the chamber cavity over the seam.

- Gas bubbles forming in the indicator solution reveal through-hole defects, enabling visual identification by the operator.

This method provides quick and reliable results, making it ideal for routine inspections.

Technical Specifications

| Parameter | Specification |

|---|---|

| Leak Detection Threshold | 10⁻⁴ m³·Pa/s |

| Monitoring Performance | ≥30 m²/h |

| Geometric Dimensions | 150 x 300 x 35 mm |

| Window Size | ≥210 x 65 mm |

| Weight | ≤0.8 kg |

Applications

The Vacuum Box DELTA-VB300 is an essential tool for:

- Tank Wall and Bottom Inspections: Detecting leaks in storage tanks.

- Field and Workshop Use: Suitable for diverse environments, including limited-access areas.

Why Choose the DELTA-VB300?

- Precision and Reliability: Delivers accurate results for critical weld inspections.

- User-Friendly Design: Lightweight, portable, and easy to operate.

- Enhanced Productivity: Monitors up to 30 m²/h, saving time on large-scale inspections.

- Standards-Approved: Meets international quality and safety standards for NDT equipment.

Order the DELTA-VB300 Today

Streamline your non-destructive testing (NDT) processes with the DELTA-VB300 Vacuum Box.

Contact us now for more details or to request a quote!

We also offer a variety of technical diagnostic and non-destructive testing equipment to meet your needs.