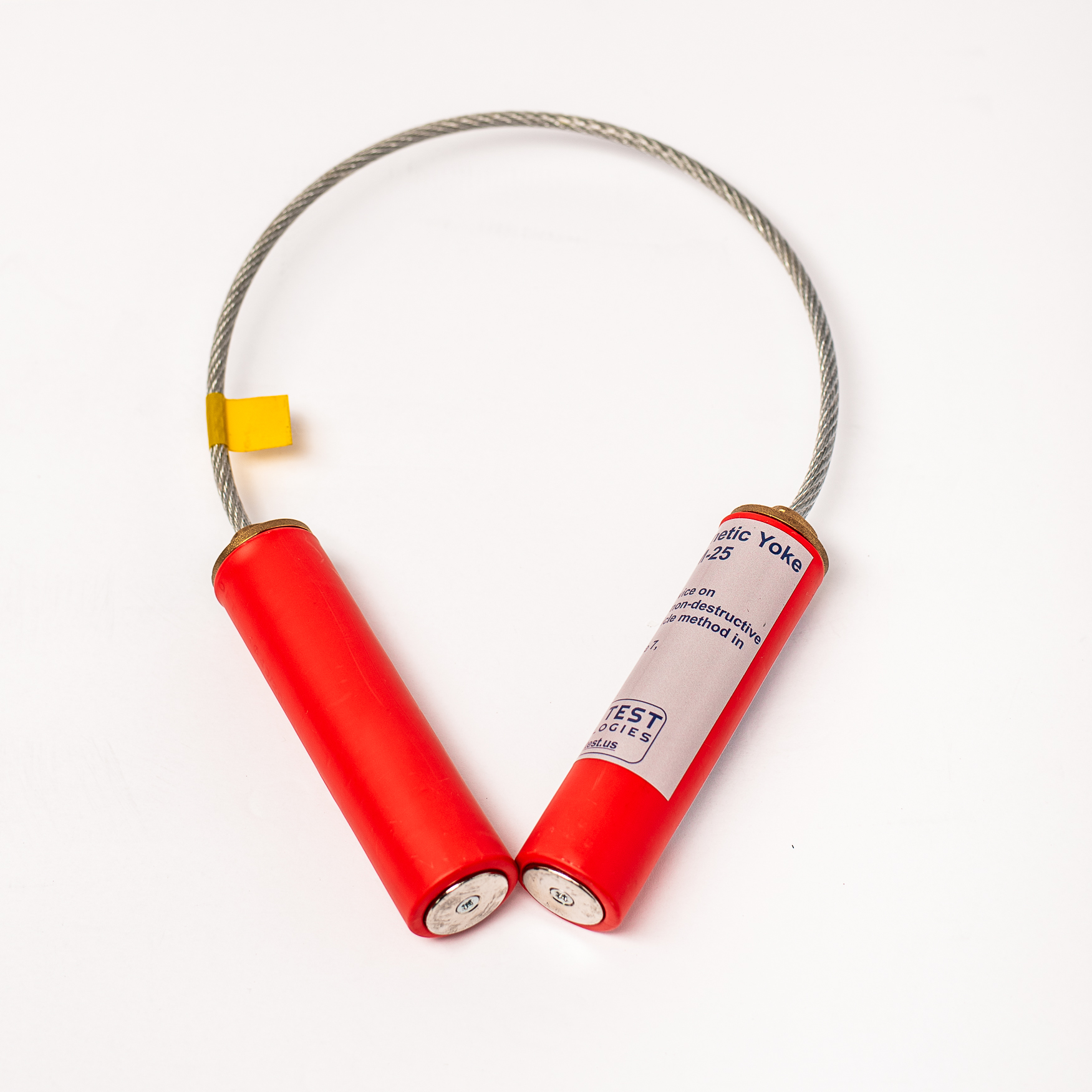

Permanent Magnetic Yoke DELTA PM-25

Permanent Magnetic Yoke DELTA PM-25 for Magnetic Particle Testing

The Permanent Magnetic Yoke DELTA PM-25 is a high-performance tool designed for non-destructive testing (NDT) using the magnetic particle method. It effectively detects surface and sub-surface defects in ferromagnetic materials, ensuring compliance with industry standards, including ASTM E1444, ASTM E709, ASTM 3024, and ASME Section V, Article 7.

Ideal for inspecting welded joints and metal surfaces, this magnetic yoke generates a powerful applied magnetic field to reveal flaws in critical product areas.

Key Features of the Permanent Magnetic Yoke DELTA PM-25

- Advanced Magnetic Pole Design: Provides precise magnetization of the product sections. The poles can be positioned in the same plane or at perpendicular angles, creating a directional magnetizing field.

- Versatile Application: Perfect for use in workshops, laboratories, and field conditions, including high-altitude facilities and environments where power supply is unavailable or restricted by safety regulations.

- Wide Operating Range: Functions in extreme temperatures from -30°C to +50°C with humidity levels up to 95%.

Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturing Method | Vacuum baking of powdered materials |

| Magnet Material | Fe-Nd-B alloy |

| Weight Lift (lb) | 50 (22.7 kg) |

| Magnetic Induction (mT) | 320 (open poles), 300 (5 mm gap) |

| Dimensions (mm) | Ø32×760 |

| Weight (kg) | 0.5 |

Why Choose the DELTA PM-25?

The DELTA PM-25 offers unmatched reliability for detecting defects in ferromagnetic materials. Its lightweight and portable design make it a go-to solution for NDT professionals working in challenging environments. The device meets the highest safety standards, making it suitable for areas with strict operational guidelines.

What’s Included in the Box:

- DELTA PM-25 Permanent Magnetic Yoke – 1 unit

- User’s Manual – 1 copy

- Magnetic Shunt – 1 unit

Applications:

The DELTA PM-25 is the ideal choice for:

- Non-destructive testing of welded joints and metal surfaces.

- Use in oil and gas, aerospace, and construction industries.

- Field inspections where power supply is limited or unavailable.

Order the Permanent Magnetic Yoke DELTA PM-25 Today

Enhance your NDT inspections with the reliable and robust DELTA PM-25 Permanent Magnetic Yoke.

Contact us now for more details or to request a quote!

We also offer a variety of technical diagnostic and non-destructive testing equipment to meet your needs.