A1610 BondVisor – Mechanical Impedance (MIA) Flaw Detector

A1610 BondVisor – Handheld Mechanical Impedance (MIA) Flaw Detector

The A1610 BondVisor – Mechanical Impedance (MIA) Flaw Detector is a handheld NDT device designed to detect delaminations, voids, and other material defects in laminated components, bonded structures, and honeycomb panels. Using mechanical impedance analysis (MIA), it identifies subtle changes in material stiffness caused by flaws, without the need for coupling liquids.

The spring-loaded sensor ensures stable readings on rough or uneven surfaces, making it ideal for in-field NDT laminate inspections.

Key Features of the A1610 BondVisor MIA Flaw Detector

- Rapid Start for Operators: Minimal training required for new users.

- Easy In-Field Calibration: Automatic sensor calibration directly on the inspection object.

- Reliable Performance: Works consistently on rough, curved, or uneven surfaces due to spring-loaded sensor design.

- Custom Sensor Options: Tailored sensors for specific material combinations available upon agreement.

- Dry Coupling Operation: Eliminates the need for gels or liquids during inspection.

Applications

The A1610 BondVisor is widely used for non-destructive testing (NDT) of laminated composites and bonded joints. It is especially effective for detecting delaminations, bond line weaknesses, and impact damage in a variety of materials.

Compatible Materials and Material Combinations

| Material | Typical Application |

|---|---|

| Multilayer laminates | Detecting layer defects in composites |

| Fiber-reinforced laminates | Fiber integrity inspection |

| Laminate-honeycomb bonds | Honeycomb structure testing |

| Laminate-metal bonds | Bond adhesion verification |

| Metal-metal bonds | Crack and void detection |

| Metal soldering | Joint quality assessment |

| Metal-feltmetal brazing | Continuity and tightness inspection |

| Rigid and soft foams | Void and defect detection |

| Wood laminates | Layer integrity evaluation |

Common Sources of Material Defects

- Impact from foreign objects or debris

- Hail or lightning strikes

- Heat-induced strength loss

- Material thickness variations

- Osmosis damage in fiberglass boats

Technical Specifications

| Parameter | Specification |

|---|---|

| Measurement Principle | Mechanical Impedance Analysis (MIA) |

| Inspection Range (Two MIA Transducers) | 0.15 – 13 mm / 0.006 – 0.5 in (depending on material) |

| Flaw Detection Capability | Laminates: > 8 mm / 0.3 in Metal alloy bonds: > 0.5 mm / 0.02 in |

| Sizing Accuracy | < 25% |

| Transmitter Type | Pulse excitation |

| Electronics Unit Dimensions | 159 × 77 × 35 mm / 6.3 × 3 × 1.4 in |

| Weight | 0.3 kg / 0.66 lbs |

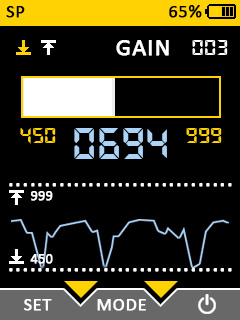

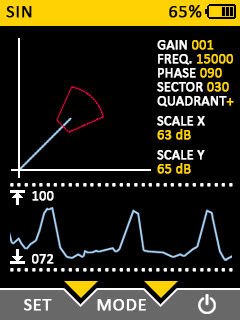

| Display | 2.4-inch color TFT, 240×320 pixels |

| Battery Type | 3 × NiMH rechargeable batteries ≥ 2700 mAh |

| Battery Life | Up to 20 hours |

| PC Interface | USB (load user presets and data transfer) |

| Operating Conditions | Temp: 10 – 50 °C / 50 – 122 °F Humidity: up to 98% at 20 °C |

Standard Delivery Kit

| Component | Quantity |

|---|---|

| Electronics unit | 1 |

| Single-element MIA transducer | 1 |

| Dual-element MIA transducer | 1 |

| Reference block Co-91 | 1 |

| Replaceable NiMH battery | 3 |

| USB data cable | 1 |

| Flash drive with recovery | 1 |

| Power supply | 1 |

| Warranty certificate | 1 |

| Hard carrying case | 1 |

Why Choose A1610 BondVisor?

- Portable and Handheld: Easy to use anywhere, perfect for field inspections.

- Precise NDT Measurements: Detects flaws in laminates, honeycomb, metals, foams, and wood.

- Long Battery Life: Up to 20 hours of continuous operation for extended inspections.

- User-Friendly Interface: Clear 2.4-inch color display and easy calibration.

Contact us today for more information or to request a quote! We offer a wide range of non-destructive testing (NDT) equipment including handheld flaw detectors, honeycomb testing devices, and BondVisor MIA systems to meet your inspection needs.