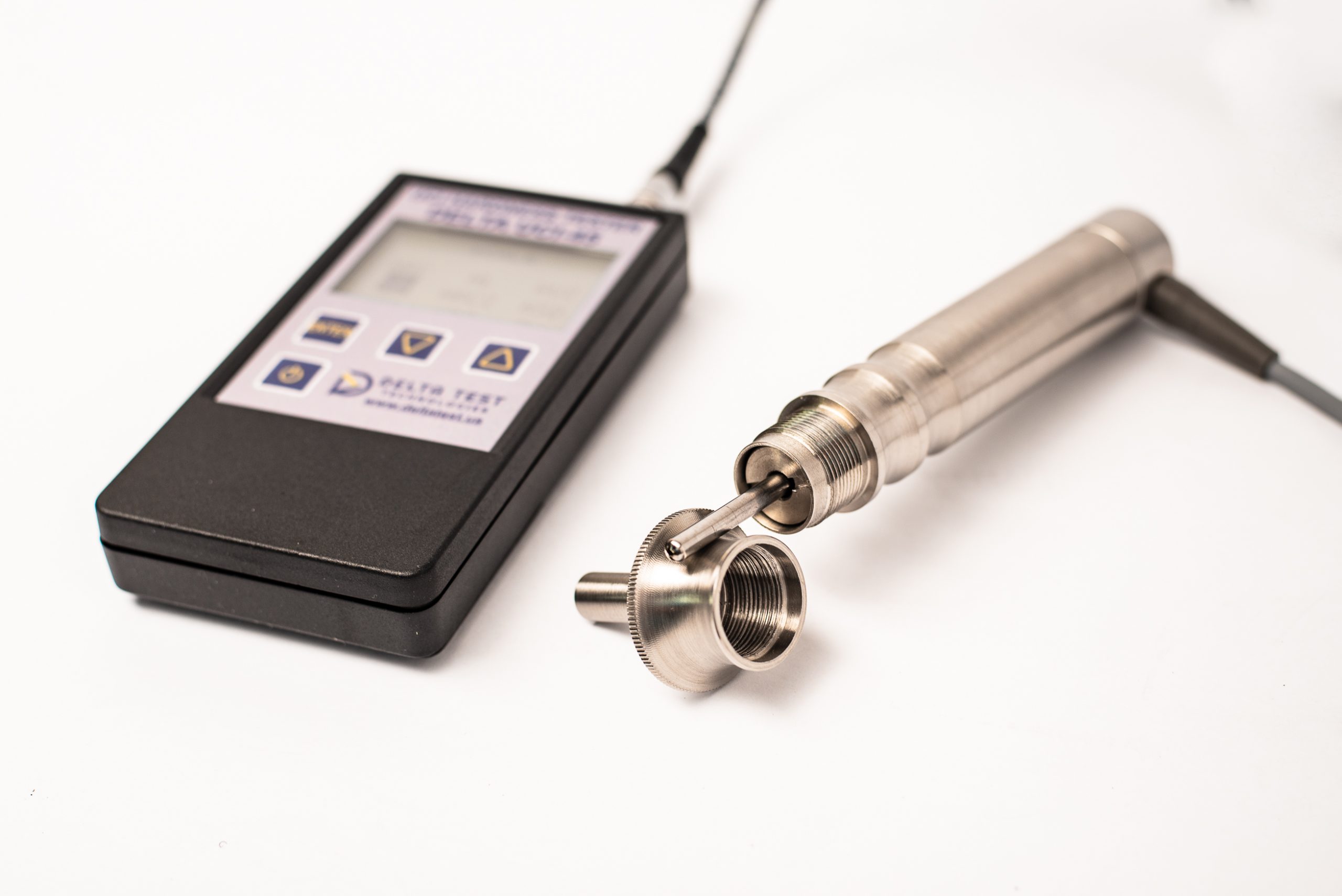

Portable UCI Hardness Tester DELTA UCI-45

DELTA UCI-45 Portable UCI Hardness Tester

The DELTA UCI-45 is a high-performance, portable UCI hardness tester designed for fast and reliable hardness testing of structural and carbon steels. Built for versatility and precision, it supports multiple hardness scales including Brinell (HB), Rockwell (HRC), Vickers (HV), Shore D, and custom user-defined scales, making it ideal for industrial, laboratory, and field applications.

Fast and Reliable Measurements

The innovative fast probe delivers results in less than a second, outperforming traditional testers that require prolonged stabilization.

Human Error Reduction

Minimizes operator influence to ensure consistent, reliable readings even under challenging conditions.

Key Features

-

Advanced UCI testing (Ultrasonic Contact Impedance, per ASTM A1038)

-

Compatible with multiple hardness scales: HRC, HB, HV, Shore D, Rm, and user-defined

-

Optimized for thin-walled and lightweight parts

-

Backlit monochrome display for low-light environments

-

Built-in statistical analysis and averaging functions

-

Compact, IP54-rated design for dust and moisture protection

-

Full measurement capability in any orientation

-

USB data output for seamless PC connectivity

-

Long-lasting operation with 2 AA batteries, auto shut-off, and battery monitoring

Reliable and Easy-to-Use

Engineered for express hardness testing on parts of any size or geometry, the DELTA UCI-45 uses the Ultrasonic Contact Impedance (UCI) method. It is perfectly suited for field inspections, gear testing, tooth flanks, roots, and other hard-to-reach surfaces. The lightweight device features manual operation and consists of a main unit and a UCI probe with a built-in cable.

Versatile Calibration & Materials Compatibility

The UCI-45 is pre-calibrated for low-alloy and unalloyed steels using standard scales (HRC, HB, HV) and provides tensile strength (Rm) measurements derived from the Brinell scale. It can also be quickly calibrated on-site for other materials, including high-alloy steels, aluminum, and titanium, as long as the Young’s modulus of the material is known.

Portable UCI Hardness Tester DELTA UCI-45 Supported Hardness Scales

| Scale Type | Label | Availability |

|---|---|---|

| Rockwell C | HRC | Built-in |

| Brinell | HB | Built-in |

| Vickers | HV | Built-in |

| Shore D | HSD | Requires programming |

| Rockwell C (Alt.) | HRC2 | Requires programming |

| Brinell (Alt.) | HB2 | Requires programming |

| Vickers (Alt.) | HV2 | Requires programming |

| Shore D (Alt.) | HSD2 | Requires programming |

| Tensile Strength | Rm | Converted from HB scale |

Portable UCI Hardness Tester DELTA UCI-45 Technical Specifications

| Parameter | Value |

|---|---|

| Hardness Scales | HRC (20–68), HB (95–450), HV (95–950), Rm (370–1500 MPa) |

| Resolution | 0.1 (HRC), 1 (HB, HV, Rm) |

| Accuracy | ±3.0 HRC, ±5% (HB, HV) |

| Power Supply | 2 × AA batteries |

| Battery Life | 50 ± 10 hours |

| Max Surface Roughness | 2.5 Ra |

| Minimum Test Object Weight | 1.0 kg* |

| Minimum Test Object Thickness | 4.0 mm* |

| Operating Temperature | 5°C to 40°C |

| Weight (with batteries) | 0.15 kg |

| Display | Monochrome LCD with backlight |

| Dimensions | 122 × 65 × 23 mm |

What’s Included

-

Main display unit – 1 pc

-

UCI probe with built-in cable – 1 pc

-

AA batteries – 2 pcs

-

USB data cable – 1 pc

-

Protective leather soft case – 1 pc

-

Rugged carrying case – 1 pc

-

PC software for data transfer – 1 pc

-

User manual – 1 pc

Download Software for DELTA UCI-45

Looking for a compact, durable, and accurate portable hardness tester? The DELTA UCI-45 delivers lab-grade performance wherever you need it — from production floors to field inspections.

Contact us now for more details or to request a quote!

We also offer a variety of technical diagnostic and non-destructive testing equipment to meet your needs.